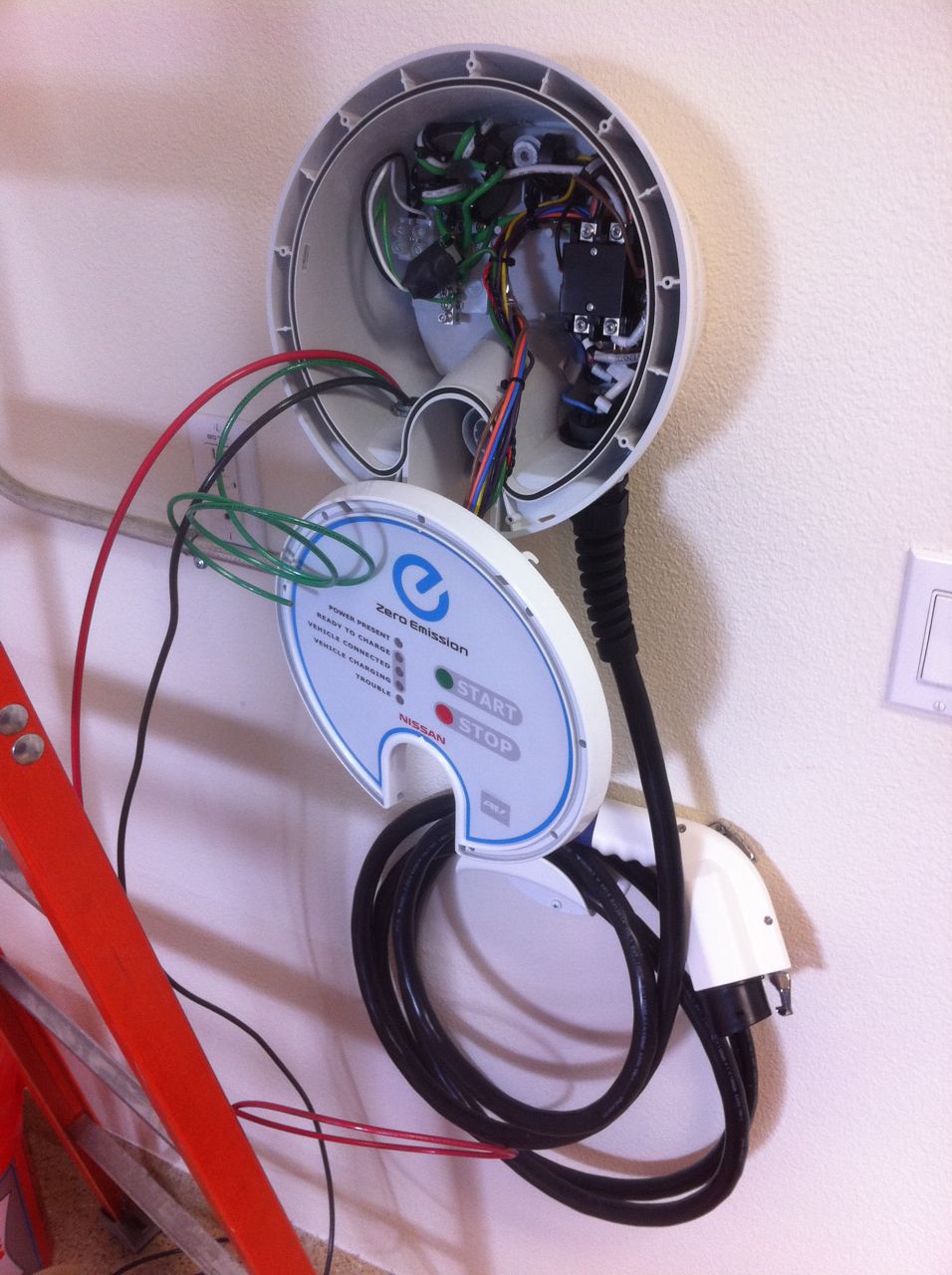

Today the Aero Vironment charging dock installation was completed so that we can start charging the Leaf at 240V. I took the opportunity to also pre-wire the garage for a second unit in front of where I park the Yaris. Whether I install another Aero Vironment dock or one from a different manufacturer, the hard work of running the lines from the panel to the garage is done. Here is the unit powered up and ready to charge an EV:

I took the photo below while the unit was still open and not yet wired so that you can see some of the inner workings. Like an EV, it has a contactor inside that is open until it receives a signal from the J-1772 plug telling it to close and energize the wire and charge the car. This signal is sent from the car via the proximity pin on the J-1772. It looks like this safety feature will require me to investigate a unit for my Yaris that can duplicate this signal so that I can take advantage of charging stations with the J-1772 plug such as my garage.

I took the photo below while the unit was still open and not yet wired so that you can see some of the inner workings. Like an EV, it has a contactor inside that is open until it receives a signal from the J-1772 plug telling it to close and energize the wire and charge the car. This signal is sent from the car via the proximity pin on the J-1772. It looks like this safety feature will require me to investigate a unit for my Yaris that can duplicate this signal so that I can take advantage of charging stations with the J-1772 plug such as my garage.