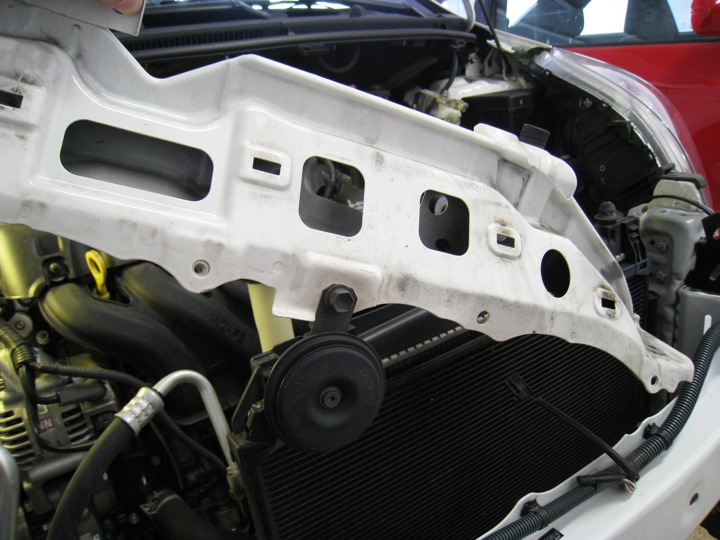

In order to get the engine and transmission pulled from the engine bay, the drive shafts need to come out of the transaxle and wheel hubs. After removing the drivers side wheel/tire, this is what the wheel hub, brake assembly, and front suspension looks like:

After removing a few nuts and retaining pins, I made good use of a ball joint separator I ordered online and popped the lower suspension arm free. Next, I proceeded to pull the outboard drive shaft spline out of the wheel hub and swing it out of the way. I repeated these steps on the passenger side wheel hub.

After removing a few nuts and retaining pins, I made good use of a ball joint separator I ordered online and popped the lower suspension arm free. Next, I proceeded to pull the outboard drive shaft spline out of the wheel hub and swing it out of the way. I repeated these steps on the passenger side wheel hub. Below is a close-up of the splines as viewed from the back side of the hub.

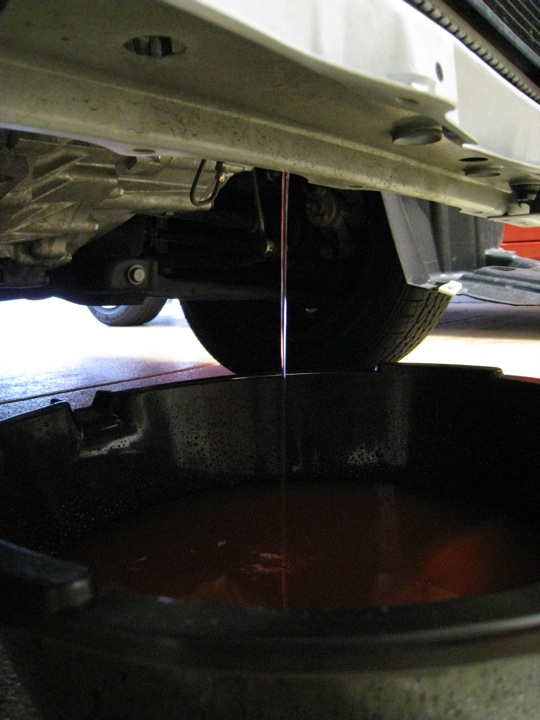

Below is a close-up of the splines as viewed from the back side of the hub.  The first step to pulling the drive shafts out of the transaxle is to remove the manual transaxle oil. Out comes the plug and the oil runs into a drain pan. This stuff is really dark.

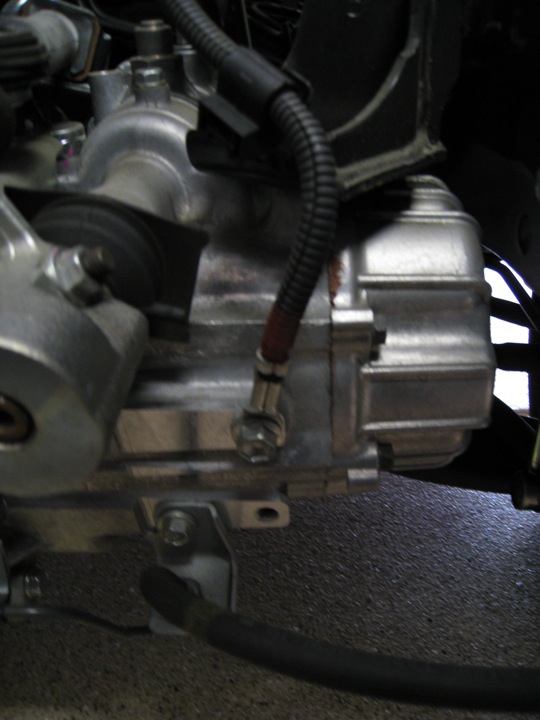

The first step to pulling the drive shafts out of the transaxle is to remove the manual transaxle oil. Out comes the plug and the oil runs into a drain pan. This stuff is really dark. Can you see that notch in the black metal (above the clamp holding the protective boot and below the barcoded label)? The manual says to use a slide hammer with a special hook attachment at the end to snag the edge of that notch to yank the drive shaft out of the transaxle.

Can you see that notch in the black metal (above the clamp holding the protective boot and below the barcoded label)? The manual says to use a slide hammer with a special hook attachment at the end to snag the edge of that notch to yank the drive shaft out of the transaxle. Unfortunately, this step has me temporarily stuck. I've tried several tools, several methods, and read numerous accounts of how people were able to remove similar drive shafts from Toyotas. For now, none of these approaches have succeeded. Until I can figure out how to get around this issue, I can't proceed to unbolt the engine mounts from the chassis and remove the last of the internal combustion components. Roadblock #1.

Unfortunately, this step has me temporarily stuck. I've tried several tools, several methods, and read numerous accounts of how people were able to remove similar drive shafts from Toyotas. For now, none of these approaches have succeeded. Until I can figure out how to get around this issue, I can't proceed to unbolt the engine mounts from the chassis and remove the last of the internal combustion components. Roadblock #1.